In the world of materials science and engineering, corrosion is a persistent and costly problem. From the structural integrity of industrial components to the longevity of everyday consumer products, corrosion poses a significant threat. To combat this issue, rigorous testing methods have been developed to assess the corrosion resistance of materials. One such method is ASTM G48 testing. In this blog, we’ll delve into the intricacies of ASTM G48 testing, providing a comprehensive understanding of its purpose, procedures, and significance.

What is ASTM G48 Testing?

ASTM G48 is a widely recognized test method that evaluates the resistance of stainless steel and related alloys to crevice corrosion when exposed to aggressive chloride-containing environments. Crevice corrosion typically occurs in narrow gaps or crevices where oxygen levels are reduced, making these areas more susceptible to corrosion. The ASTM G48 test helps manufacturers, engineers, and scientists determine the performance and durability of materials in chloride-rich environments, which is essential for industries such as petrochemical, maritime, and chemical processing.

The Importance of Crevice Corrosion Testing

Crevice corrosion can be particularly insidious. It often occurs in hidden or hard-to-reach areas of metal structures, making it difficult to detect and mitigate. As such, it can lead to unexpected failures in critical components, posing safety risks and incurring costly maintenance and repair expenses. By subjecting materials to ASTM G48 testing, researchers can assess the likelihood of crevice corrosion and develop strategies to prevent it.

Procedure of ASTM G48 Testing

The ASTM G48 test primarily evaluates stainless steel and related alloys by immersing them in a solution of ferric chloride (FeCl3) at a specific temperature for a set period. The key steps in the procedure are as follows:

Sample Preparation: A specimen of the material under consideration is carefully machined and polished to remove surface imperfections.

Immersion in Ferric Chloride Solution: The prepared sample is then immersed in a solution of ferric chloride at a controlled temperature. The temperature and exposure time may vary based on the specific ASTM G48 test method chosen, such as Method A (faster test) or Method B (more severe test).

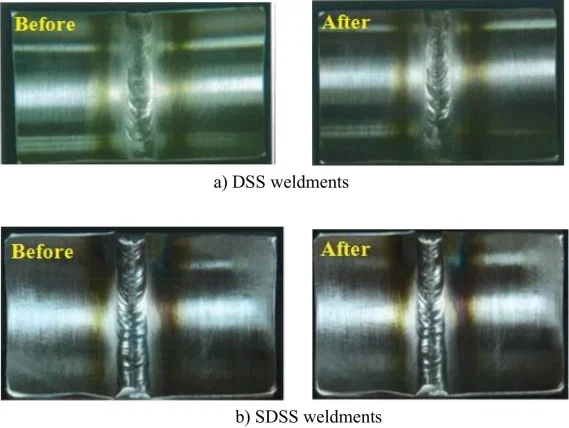

Evaluation of Crevice Corrosion: After exposure, the sample is examined for signs of crevice corrosion, such as pitting or staining. The depth and extent of corrosion are assessed to determine the material’s performance.

Recording Results: Test results are recorded, and the extent of crevice corrosion is typically measured using various methods, including weight loss, visual inspection, and corrosion product analysis.

Significance and Interpretation of ASTM G48 Testing

The results of ASTM G48 testing are crucial for understanding how stainless steel and related alloys will perform in chloride-rich environments. The test helps identify materials that are resistant to crevice corrosion, enabling engineers and manufacturers to make informed decisions about material selection for specific applications. The test results can also inform maintenance practices and the development of protective coatings or treatments to prevent corrosion.

ASTM G48 testing is a valuable tool for assessing the corrosion resistance of stainless steel and related alloys in chloride-containing environments. By subjecting materials to this test, engineers and scientists can gain insights into the potential for crevice corrosion and make informed decisions regarding material selection and corrosion prevention strategies. As industries continue to push the boundaries of material performance, ASTM G48 testing remains a fundamental element in ensuring the reliability and safety of critical structures and components.

Read our article on for other corrosion testing method ASTM A262 : Intergranular Corrosion Testing