In this article we will discuss about the P91 material basics, welding requirement, consumable selection, welding process selection, microstructure, application.

Weld Consumable Excel Calculator Download Link

Weld Consumable Calculation PPT Free Download For Training

Welding Symbols PPT Free Download For Training

Welding joint and symbols guide PDF of 96 pages

P91 Material

The use of P(T)91 materials is worldwide. There are various sources for base materials, welding consumables, and fabrication or components. The art is such that few welding problems are encountered. The desire to increase efficiency has introduced a need for advanced materials with superior material properties at higher temperatures. Depending on strength and/or corrosion criteria, materials such as P(T)23, P(T)24, E911, P(T)92, and P(T)122 have been developed.

Increasingly demanding material requirements found in piping and boiler construction for industries such as power generation and petrochemical have made a specific type of chromium-molybdenum steel pipe — referred to as grade P91 — a frequent choice because of its ability to withstand high pressures and high temperatures. P91 is used in many critical applications that require significant strength at high temperatures, including superheaters, headers and steam lines.

However, P91 is a higher-cost material that presents some challenges in fabrication. Achieving sound welds with P91 pipe requires operator skill; careful control of heat treatment before, during and after welding; and choosing appropriate low-hydrogen filler metals.

In addition to following specific procedures and best practices to achieve high-quality welds, a change in welding processes can lead to significant productivity gains and reduce the time it takes to train new welding operators in P91 welding applications.

Modified. 9Cr-lMo is the best material for higher service temperature. It has attractive properties:

- High creep strength with good ductility

- Very High resistance to cracking,

- High thermal conductivity and low thermal expansion coefficient.

The basics of P91:

P91 is a type of creep strength enhanced ferritic (CSEF) alloy, which are steels designed to retain strength at extremely high temperatures. The P91 abbreviation represents the material’s chemical composition: 9 percent chrome and 1 percent molybdenum.

The material is used in high temperature, high pressure steam piping not only because it retains strength at elevated temperature but also because it resists failure due to “creep,” which is the tendency of a solid material to move slowly or deform permanently under the influence of mechanical stresses. P91 also resists corrosion better than steel alloys used previously in these applications. Because of these advantages, P91 is used extensively in power generation applications, such as for high pressure steam lines.

Due to the critical nature of these applications, any defects in the weld can result in cracking and eventual part failure. Failures in high-pressure steam pipe can be catastrophic, causing ruptures, tank or valve explosions, or other serious incidents that can result in fatal injuries. As a result, codes and procedures for P91 applications are stringent.

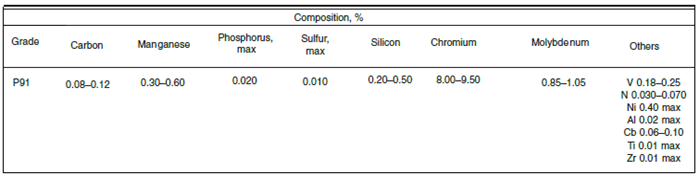

Chemical Composition of P91 Material:

The improvement in properties of modified 9Cr-1Mo are achieved by controlled additions of vanadium,niobium,and nitrogen,combined with a normalize-and -temper heat treatment. The chemical composition of modified 9Cr-1Mo.

Carbon,C: Increases the mechanical strength and forms carbide and carbonitrides with Cr, Nb, V which improve the creep strength. It is an austenitizing elements (retards the formation of delta ferrite).

Chromium, Cr: Improves steam oxidation and corrosion resistance; increase hardenability

Molybdenum, Mo: Improve strength at high temperature.

Nitrogen, N: Increases the mechanical strength and form carbonitrides with Nb and V which improve the creep strength. It is an austenitizing element and retards the formation of delta ferrite.

Niobium, Nb: Carbide and nitride former, very important for creep strengthening.

Nickel, Ni: Lowers AC1 temperature and above 0.6% reduce creep resistance.

Application of grade 91 steel:

- Superheaters, headers and steamlines.

- Typical working temperatures between 540°C to 610°C

Selection of Welding Process

The most common welding processes for P91 fabrication are GTAW (TIG), SMAW (MMA), FCAW and SAW.

GTAW typically exhibits higher toughness than weld metal deposited other welding process.

Fabrication of P91 Material

Fabrication of P91 material is not simple as Carbon Steel material. Many tricks are involved in P91 fabrication.

Below is the recommendation for the fabrication of P91 material:

Cutting

Cutting of P91 material shall be done only with Band Saw. Edge Preparations (EP) shall be done only by machining, however gas cutting can also be done but at least 3 mm of material required to be remove to avoid high hardness due to gas cutting process. All Edge Preparations (EPs) shall be subjected to Liquid Penetrant Test (LPT) or MT. Weld Build-up on EP shall be prohibited.

Weld Fit-up

- Weld edge preparation shall be done on bevelling machine or gas cutting.

- ID matching as well as OD of piping and fitting shall be ensured at the time of weld fit-up.

- Weld fit-up is done either by clamping (for NB≥150) or by welding a bridge of P91 material (for NB < 150). Minimum pre heat (204°C) shall be maintained prior to tack welding. After completion of tacking, the tack welded area shall be covered with thermally insulated material for at least one hour. The Root gap of 2-3.5 mm require to maintain. Misalignment shall be limited to 1.0 mm, so as to avoid any root side welding defects.

- Cleaning of the fit-up area and the joint to be welded is done thoroughly with Stainless Steel wire brush or Stainless Steel wire wheel.

- Purging dummy arrangement for GTAW welding

- Thermocouple shall be attached at a distance of 3 times the thickness or 75 mm, whichever is greater, to measure the Preheat and interpass temperature. The Thermocouple shall be attached by Capacitor Discharge method, following applicable WPS. Two numbers of thermocouples shall be attached on the circumference 180⁰ apart on each side. The difference between any two temperatures shall not be more than 10⁰C.

Preparation before & during welding

Welding of P91 Material:

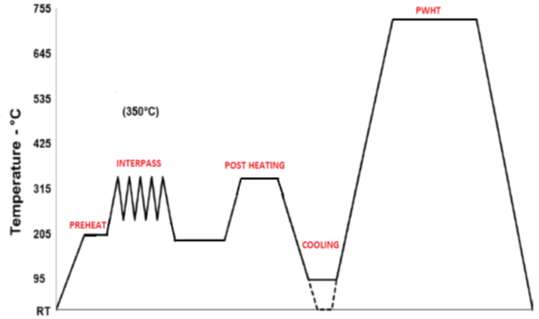

Preheating→Preheat Maintenance→Welding→Post Heating→Cooling below 96°C→PWHT

Preheat:

A minimum preheat of 204°C shall be maintained throughout the welding process. Heating shall be by electric resistance method/induction heaters. A minimum preheat of 204°C shall be used for tack welding. For tack welds incorporated into the final weld, preheat shall be maintained at 204°C through the completion of welding. Preheat and Interpass temperatures shall be monitored and recorded manually by Thermo pens or Laser Guns. A manual record for Interpass temperatures shall be maintained for each pass. The minimum preheat temperature may be reduced to 150°C when the weld thickness is less than ½ inch (13mm) and welding is performed by the GTAW process. Preheat can only be reduced to 150°C when allowed by the governing Code.

Recommended preheat temperature for Grade 91 material as per various codes and standards:

205°C (Non-Mandatory appendix “R”, ASME Section VIII Div.1)

200°C (Table 131.4.1-1, ASME B31.1 & Table 330.1.1 of ASME B31.3)

150°C for thickness ≤13 mm & 205°C for thickness > 13 mm (Table PW-38-1, ASME Section 1)

Preparation after Welding

Hydrogen Bake-out:

After completion of welding it is to be ensured that joint put in Hydrogen Back-out. Hydrogen Baking is to be performed and maintained with Resistance heating method. The weld shall receive a post heating between 300°C to 350°C.The weld shall be post heated for a minimum of 2 hours and a maximum of 3 hours and then wrapped with insulation and slow cooled down to at least 96°C, at which time the weld may be unwrapped. For welds deposited by GTAW process, the post heat temperature may be reduced to 260°C minimum. After satisfactory completion of Hydrogen baked out, complete weld joint and HAZ shall be visually examined for any surface Indication, visually accepted welded joint shall be sent for PWHT. There shall not be delay of more than 5 days for PWHT, after completion of Hydrogen baking of the joint.

Cooling after Post Heating:

To achieve post weld tempering of the martensitic structure, it is important that the weld joint cools below martensitic temperature before heat treatment. The martensitic finish (Mf) temperature of P91 is approximately 96°C. Therefore, it is recommended to cool below 90°C to allow complete transformation of the weld metal and heat affected zone.

Post Weld Heat Treatment (PWHT) of Grade P91:

PWHT is one of the most important factors in producing satisfactory weld of P91 material. Regardless of the thickness or diameter preheating and PWHT are mandatory to reduce hardness and to restore ductility in the weld and HAZ. Selection of P91 steel PWHT temperature range is very tricky as we have to follow construction code and also depends & affected by percentage of Mn+Ni as it lowers the lower critical transformation temperature. Selection of proper soaking temperature is very important in case of P91 material. If the PWHT temperature is too low, the welds joints lead to insufficient toughness and high hardness due to the unsatisfactory tempering effect and if the PWHT temperature is too high, the tensile strength at ambient and elevated temperatures becomes inadequate due to over tempering effect.

PWHT temperature as per various codes and standards:

- 705-785°C (as per Table PW-39-5, ASME Section 1)

- 705°C Minimum and for Max. temp. refer below (as per Table UCS 56-11, ASME Section VIII Div.1)

For welds made with matching Grade 91 filler metal (e.g., AWS A.5.5 E90xx-B91, ISO EN CrMo91), the maximum holding temperature shall be determined as follows:

- If the Ni+Mn content of the filler metal≤1.0%, the maximum PWHT temperature shall be 790°C.

- If the Ni+Mn content of the filler metal>1.0% but ≤ 1.2%, the max. PWHT temperature shall be 780°C.

- If the Ni+Mn content of the filler metal>1.2%, the maximum PWHT temperature shall be at least 10°C below the lower critical transformation temperature (Ac1)

- 705-775°C (Table 132.1.1-1, ASME B31.1 & Table 331.1.1 of ASME B31.3)

Recommended PWHT temperature for P91 Material are 740 to 760°C

Preventive measures during any interruption of heating/welding at any stage:

Weld Interruption-Weld interruptions are defined as either an unintentional loss of preheat or reductions below the minimum preheat temperature after welding has begun.

Welding of P91 requires heat application throughout the process. As the cycle time is long, there are chances of Heating/Welding interruption due to non-availability of-Power

- Heating/Welding equipment’s or

- Welder

- Welding consumables

Steps to be taken in case power is not available for heating during P91 Welding:

- If the power is not available before reaching Preheating temperature, heating should be discontinued and re-started when Power is re-instated.

- If the Power interrupts when the Preheat temperature is achieved, the temperature is to be maintained by any means i.e. even by LPG burners or DG-sets are available. This has to be ensured the preheat temperature is maintained till the completion of weld.

- If the power goes off during Hydrogen Baking, the Baking temperature is to be achieved and maintained by DG-sets if power goes off during hydrogen baking maximum five minutes is required to achieve the temperature by using DG-sets.

- If power goes off during Heating in PWHT cycle, continue with the temperature drop. If the drop is not below 50⁰C, proceed further. If the temperature drop is more than 50⁰C, the heating shall be re-started.

- If Power goes off during soaking period and the temperature drops from the soaking temperature, the duration of lesser temperature shall be extended in the soaking period at soaking temperature.

- If there is power cut during cooling, but before the unloading temperature, the temperature shall be raised to the soaking temperature and maintained for the additional period (as per relevant code). Cooling shall be done as per the recommended rate.

- If there is power cut during cooling, but after the unloading temperature, there is no action to be taken. Let the material be cooled at its normal course.

Steps to be taken for some of the realistic eventualities occur in shop floor during P91 welding:

- If welding power source gets failed during welding, the power source is to be replaced by a power source of similar electrical characteristics, preferably even similar make. The action has to be taken immediately. The altered Power source should also be calibrated. During the period, the Preheat temperature to be maintained.

- In case the welder has to be changed (may be due to shift change or in eventuality of illness of the welder), the thickness deposited by each welder to be recorded. During this change, the preheat temperature should not be allowed to come down than the mentioned in relevant WPS.

- It has to be ensured that the sufficient Filler wires/ baked welding electrodes are available with the welder all the time. In case the consumables are to be arranged after all the previous consumables are consumed, the preheat temperature is to be maintained and never allowed to come down than the mentioned in relevant WPS.

Filler Metal Selection for P91 material

- The performance of Grade 91 welds depends entirely on having the correct chemical analysis in the weld metal; therefore, all filler metals are purchased with test reports showing actual chemical analysis for the specific heat/lot combination that was purchased.

- Since P/T-91 is modified with vanadium, nickel, aluminum, niobium and nitrogen, it develops very high hardness. Tramp residual elements in this steel, such as phosphorous, sulfur, lead, tin, copper, antimony and other elements will segregate to the grain boundaries during solidification of the weld, and, since the weld metal is very hard, it will crack quite easily.

- It is, therefore, very important to use low residual filler metal.

- A minimum carbon content of 0.09%, a minimum niobium content of 0.03%, and a minimum nitrogen of 0.02% to ensure adequate creep strength in the weld metal.

- In addition, the sum of Mn + Ni should not exceed 1.5%.

- Manganese and nickel depress the lower transformation temperature, and as it exceeds 1.5%, the transformation temperature drops below 785ºC, narrowing the range in which heat treatment can be done safely. In addition, the Mf temperature goes down, increasing the possibility of retained austenite after PWHT.

- For SMAW, E9015-B9 electrodes are preferred. EXX15 type electrodes have no extra iron powder in the coating like EXX18 electrodes, eliminating one source of contaminants.

- All SMAW electrodes are stored in heated portable rod boxes at the welding location

- Irrespective of electrode composition shown on TC, if we start noticing crater cracks (also known as “solidification anomalies”), the filler is not low in residuals and we send it back.

Consumables Listed in ASME for Welding P91:

- SMAW 5.5 E90XX-B9

- SAW 5.23 EB9 + flux

- GTAW 5.28 ER90S-B9

- FCAW 5.29 E91T1-B9

When using SAW, a basic flux is preferred since other flux types will burn out carbon and permit elevated oxygen and nitrogen levels reducing the strength and toughness of the weld metal.

Some of the P91-Recommended consumable brand names are given as:

Oerlikon OP 76,

Bohler Marathon 54

Metrode LA 491

Kobelco PF-200S.

Heat Treatment of P91 Material

Modified 9Cr-lMo requires a normalize and temper heat treatment to fully develop its strength and toughness properties. Standard practice is to normalize between 1040 to 1090 °C to avoid objectionable grain growth, and tempering at 760 to 780 °C which allows carbides to precipitate homogeneously within the tempered fully martensitic structure.

The lower critical temperature between 830 °C to 850 °C;

The upper critical Ac3 exists between 900 to 940°C

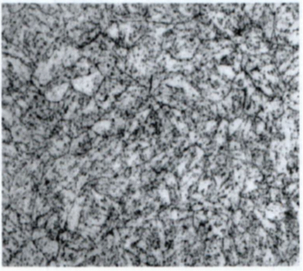

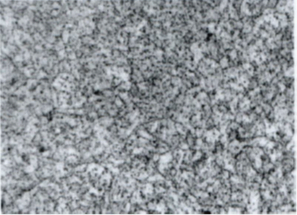

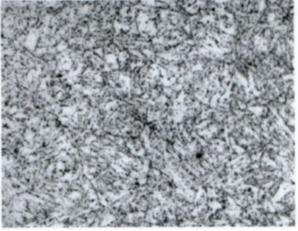

Microstructure of Grade P91

P91 steel has been widely used in power generation industry. Generally, P91 creep resisting steel is produced by normalizing and tempering.The microstructure after tempering is tempered martensite with precipitates of carbides, M23C6, and vanadium/niobium rich carbo‐nitride of the type MX (M = V or Nb and X = C or N).

Very good explanantion.

Good content to study.

Very descriptive information.

Very interesting.

Keep it up.

Fruitful information.

hi,sir

im confused why post heating in fornt of cooling 96 ,any practice ?

to drop down the temperature to martensite finish temperature, so complete martensite can be transformed