Welding, a fundamental process in metal fabrication and construction, involves joining metal components through the application of heat and pressure. Two common types of welds, butt and fillet welds, are integral in creating strong, durable joints. Understanding nomenclature and components of Butt and Fillet Welds is crucial for welders and engineers to ensure the integrity and quality of welded structures.

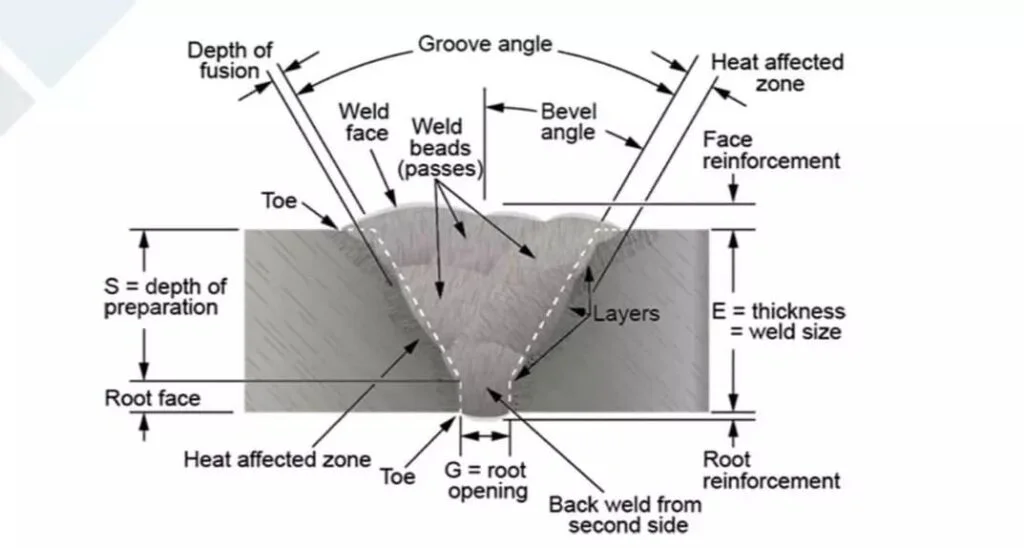

Nomenclature and Components of Butt Weld

A butt weld is formed by joining two pieces of metal along their edges to create a continuous joint. The nomenclature of a butt weld involves several key components:

- Root: The central point where the edges of the two base metals meet.

- Weld Face: The visible exterior surface of the welded joint.

- Toes: The points where the face of the weld meets the base material, forming the edges of the joint.

- Fusion Zone: The area where the base metals have melted and fused together due to the welding process.

- Weld Metal: The material deposited in the joint during welding.

- Penetration: The depth to which the weld extends into the base material, crucial for joint strength.

Achieving proper penetration and fusion is essential in butt welding, ensuring a strong and reliable joint that meets structural requirements.

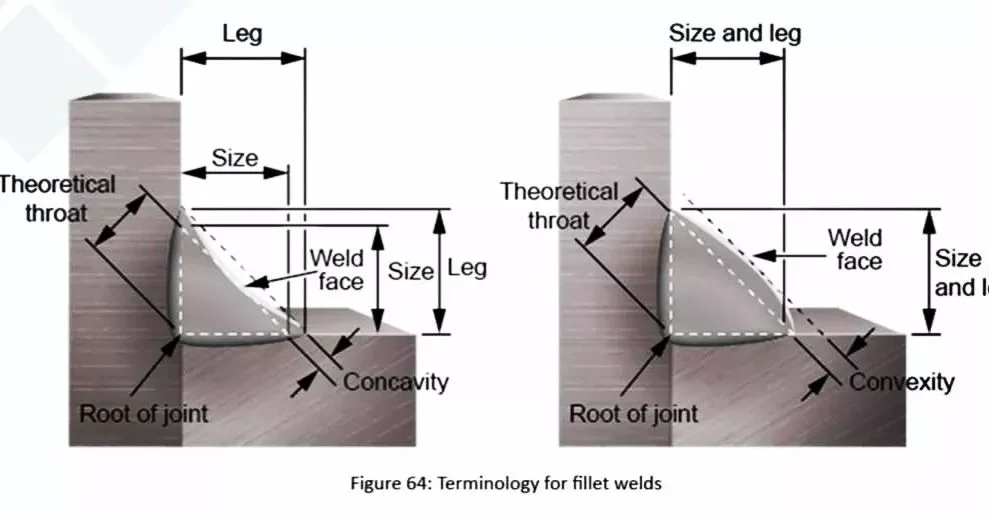

Nomenclature and Components of Fillet Weld

n contrast, a fillet weld is a triangular weld joint used to connect two surfaces approximately at right angles. The nomenclature of fillet welds includes:

- Leg: The distance from the root of the joint to the toe, measured along the triangle’s axis.

- Throat: The distance from the root of the joint to the point where the leg intersects the hypotenuse, determining the weld’s strength.

- Size: The leg length or throat thickness of the fillet weld, influencing its load-bearing capacity.

- Face: The visible surface of the fillet weld after completion.

- Root: The intersection point of the surfaces being joined.

- Fusion Zone: The area where the base metals and filler material melt and fuse together, forming a strong bond.

Fillet welds are widely used due to their versatility and strength, often found in structures subjected to varying loads and stresses.

Significance:

Understanding the nomenclature and components of butt and fillet welds is critical for welders, inspectors, and engineers. Proper weld design, dimensions, and quality directly impact the structural integrity and safety of welded components.

The accuracy of weld size, penetration depth, and fusion zone greatly influences the joint’s strength. Any deviation from specified dimensions or inadequate fusion can compromise the weld’s performance, leading to structural failures or reduced load-bearing capacity.

In conclusion, mastering the nomenclature and understanding the components of butt and fillet welds is essential for ensuring the reliability and durability of welded structures. This knowledge empowers welders and engineers to create strong, high-quality joints that meet stringent industry standards and safety requirements.