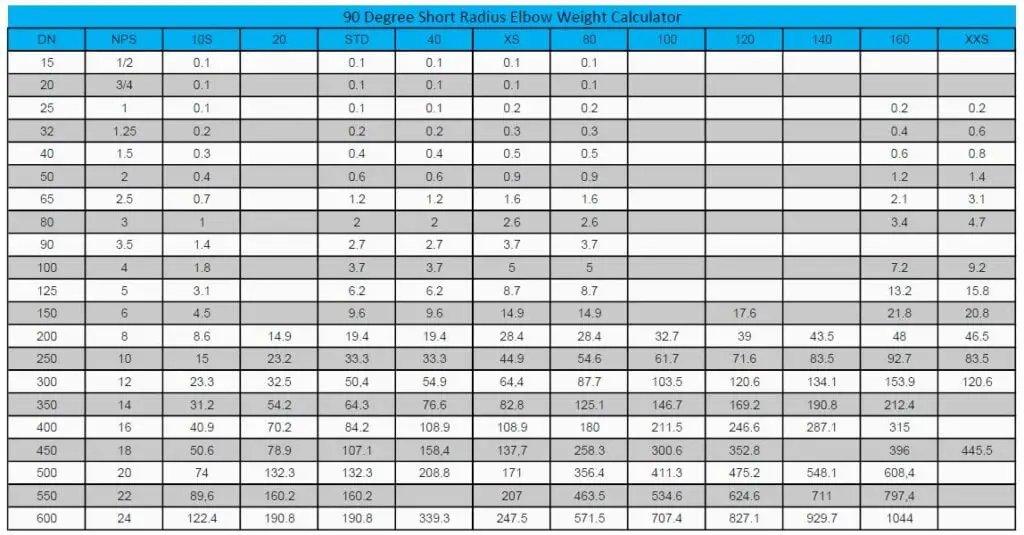

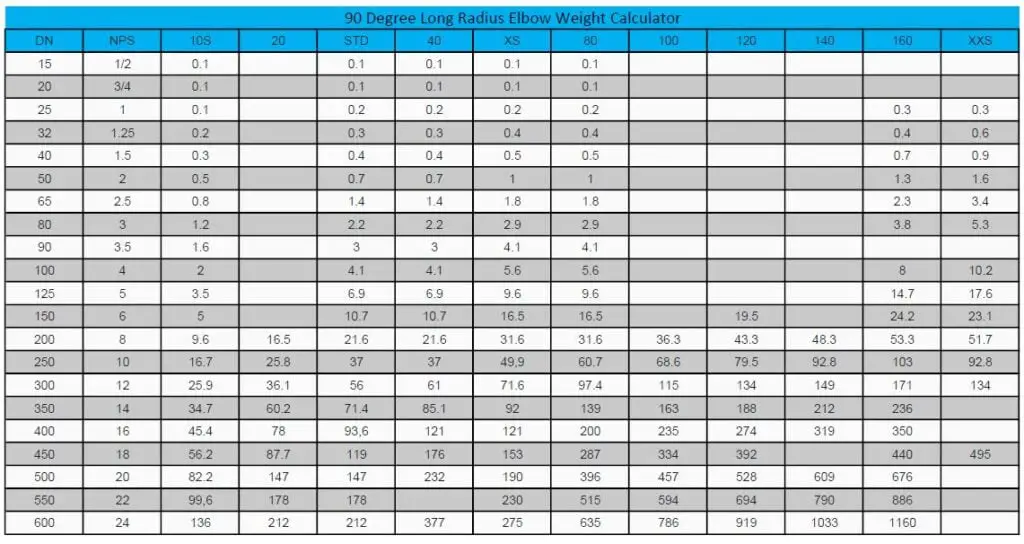

Elbow is the most commonly used fitting to change the angle or direction of the pipe run. Most commonly in 90 degrees and 45 degree turns. Elbow weight calculator and charts are also provided below for 90 degree short and long radius elbow

Knowing the approximate weight of the fittings helps us calculate the:

- Welding consumable cost for cladding

- Price calculation of item

- Freight charge of the items

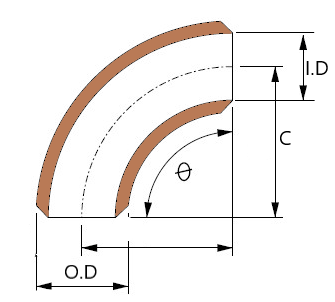

O.D= Outside Diameter of Elbow

I.D= Inside Diameter of Elbow

C= Elbow Center (Consider center to end distance of 90° Elbow as per ASME B16.9)

θ=Degree of Elbow

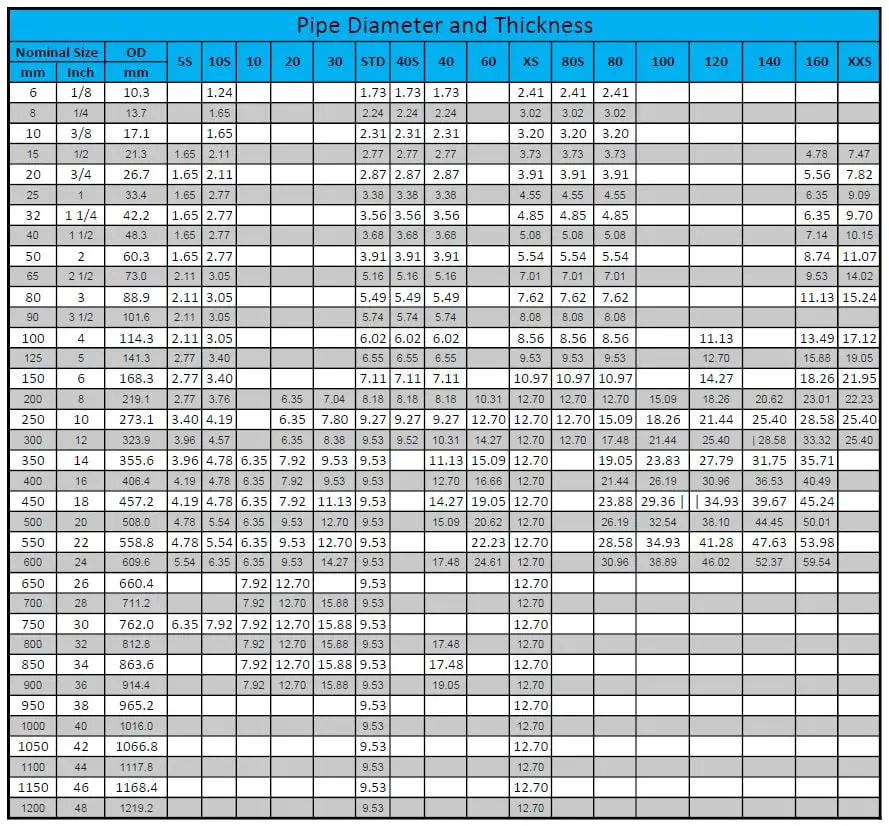

Pipe Diameter and Thickness

While calculating the weight of elbow by formula, we should know dimensions, such as outside diameter, wall thickness in millimeter and long radius ( 1.5D) or short radius ( 1D). Below is nominal pipe chart for ready reference

What are the Methods ?

- Get the weight of 90 degree elbow by chart.

- Calculate the weight by formula.

- Weigh them one by one.

When you have the outside diameter and wall thickness schedule, you can get the weight in the chart easily. But make sure the 90 degree elbow types clearly, there are two types that LR and SR. We would like to provide the each weight chart for you.

What is Formula of 90 Degree Elbow Weight Calculator

The weight formula is W=0.0387 * S*(D – S) * R / 1000, the unit is kg/piece. What’s the meaning of each letter? Let’s explain to you.

- W means Weight.

- S means Thickness in mm.

- D means Outside Diameter in mm.

- R means Radius that LR=1.5D, SR=1D.

Now we take “90 Degree Elbow LR Seamless 6″ Sch 40 BW ASTM A234 WPB” as sample. From above diameter and thickness chart, we know the outside diameter is 168.3mm and thickness is 7.11mm. The weight will be 0.0387 x 7.11 x ( 168.3 – 7.11 )x 1.5 x 168.3 / 1000 = 11kg/piece.

90 Degree Elbow Weight Chart