Gas Metal Arc Welding (GMAW), commonly known as MIG (Metal Inert Gas) or MAG (Metal Active Gas) welding, is a versatile and widely used welding process in which an electric arc is established between a consumable wire electrode and the workpiece metal. This arc generates intense heat, causing the workpiece metal to melt and fuse together. Simultaneously, a shielding gas is fed through the welding gun to protect the process from atmospheric contamination.

GMAW is a highly adaptable welding method that offers a range of benefits, making it a preferred choice in various industrial applications. This article will delve into the details of GMAW, its development, equipment used, operation, safety considerations, and the different metal transfer modes within this welding process.

Development of GMAW

The principles of GMAW date back to the early 19th century when Humphry Davy and Vasily Petrov independently discovered and experimented with electric arcs. The development of carbon electrodes for carbon arc welding followed, with the first successful metal electrodes invented by Nikolay Slavyanov and C. L. Coffin around 1890. P.O. Nobel of General Electric introduced an early predecessor of GMAW in 1920, using direct current with a bare electrode wire to regulate the feed rate. However, the use of shielding gases did not become common until later in the decade.

In 1948, the Battelle Memorial Institute developed GMAW as we know it today, employing a smaller-diameter electrode and a constant voltage power source, which significantly increased the deposition rate. However, the high cost of inert gases limited its use to non-ferrous materials. The breakthrough came in 1953 when carbon dioxide was introduced as a welding atmosphere, making steel welding more cost-effective. The short-arc variation of GMAW was released in 1958, allowing for the welding of thin materials and quickly becoming the most popular form of GMAW.

In the early 1960s, the spray-arc transfer variation emerged with the addition of small amounts of oxygen to inert gases. More recently, pulsed current has been applied, giving rise to the pulsed-spray-arc variation. Today, GMAW stands as one of the most popular welding methods, particularly in industrial settings, such as the sheet metal and automobile industries, where it is used for various applications.

Equipment for GMAW

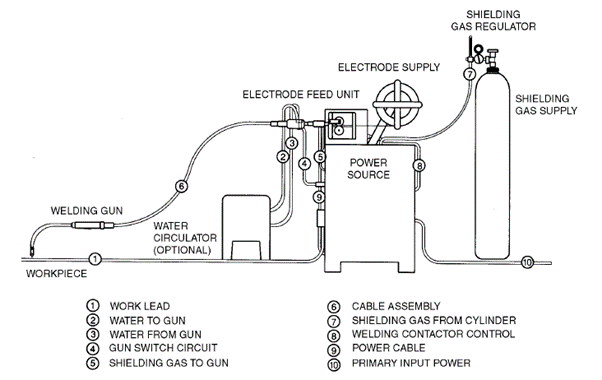

To perform GMAW, specific equipment is required:

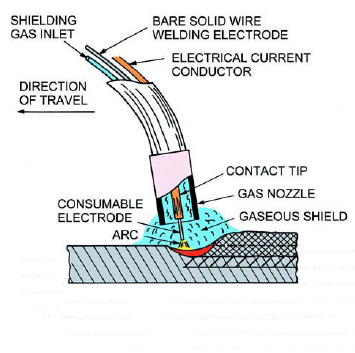

Welding Gun and Wire Feed Unit: The welding gun comprises several key components, including a control switch, contact tip, power cable, gas nozzle, electrode conduit and liner, and a gas hose. The control switch initiates the wire feed, electric power, and shielding gas flow when pressed. The contact tip, typically made of copper, transmits electrical energy to the electrode and directs it to the weld area. The power cable connects the contact tip to the welding power source. The gas nozzle ensures even gas distribution to protect the weld area, and the electrode conduit and liner guide the wire and maintain its feed. The gas hose connects to the shielding gas supply.

Welding Power Supply: A constant voltage power source is commonly used in GMAW, although constant current systems and even alternating current can be employed, depending on the application.

Welding Electrode Wire: The choice of electrode wire depends on the type of material being welded, the welding process variation, joint design, and surface conditions. The diameter of the wire can vary but generally falls within the range of 0.8 to 2.4 mm.

Shielding Gas Supply: Shielding gases are necessary to protect the weld area from atmospheric contaminants. The choice of shielding gas depends on the materials and welding process variation. Common shielding gases include argon, carbon dioxide, helium, and gas mixtures tailored to specific applications.

Operation of GMAW

GMAW is known for its ease of operation, making it accessible to welders after just a few weeks of training. The process is semi-automatic or automatic, relieving the operator of the need to maintain precise arc length or feed filler metal manually. The primary tasks for a GMAW operator include guiding the welding gun’s position and orientation along the workpiece and cleaning the gun’s gas nozzle to remove spatter buildup.

Maintaining a consistent contact tip-to-work distance (stick-out distance) is essential. Excessive stick-out can cause the wire electrode to melt prematurely, leading to an erratic arc and shielding gas dispersion. Conversely, insufficient stick-out can result in spatter buildup inside the gun’s nozzle.

The operator must also adjust welding parameters like voltage, wire feed rate, and gas flow rate to match the materials and wire size being used. Proper positioning and orientation of the welding gun relative to the workpiece are crucial, with the travel angle usually maintained at about 45 degrees for fillet welds and 90 degrees for welding flat surfaces.

Position welding, such as vertical or overhead joints, may require a weaving technique to ensure proper weld deposition and penetration, mitigating the effects of gravity on the molten metal.

Metal Transfer Modes in GMAW

GMAW offers three primary metal transfer modes: globular, short-circuiting, and spray. These modes differ in their characteristics and are chosen based on the application and materials being welded

1. Globular Transfer:

Characteristics: In the globular transfer mode, the welding wire is fed into the arc, forming large drops that detach and transfer across the arc. This mode is characterized by irregular and intermittent droplet transfer.

Applications: Globular transfer is suitable for welding thicker materials, but it can result in higher spatter levels and a less stable arc.

Advantages and Disadvantages: The advantages of globular transfer include good penetration and the ability to weld thicker materials. However, it is less efficient, and the quality of the weld can be compromised due to spatter.

2. Spray Transfer Mode

Characteristics: In the spray transfer mode, a fine, controlled stream of small droplets is propelled across the arc. This mode is characterized by a stable and continuous arc.

Applications: Spray transfer is ideal for welding thin materials, providing excellent control over the weld pool and minimizing heat input.

Advantages and Disadvantages: The advantages of the spray transfer mode include high efficiency, low spatter, and superior weld quality. However, it often requires high current and voltage settings.

3. Short Circuit Transfer Mode

Characteristics: In the short circuit transfer mode, the welding wire periodically touches and short circuits with the workpiece, creating a series of small, controlled droplets.

Applications: Short circuit transfer is commonly used for welding sheet metal and thin materials, as it produces minimal heat input and distortion.

Advantages and Disadvantages: This mode offers excellent control, low heat input, and minimal spatter. However, it may not be suitable for thicker materials due to limited penetration.

4. Pulsed Spray Transfer Mode

Characteristics: Pulsed spray transfer combines aspects of the spray and short circuit modes. It involves intermittent high-current pulses to create controlled droplet transfer.

Applications: Pulsed spray transfer is versatile, making it suitable for a wide range of materials and thicknesses, including aluminum.

Advantages and Disadvantages: It offers good control, reduced heat input, and reduced spatter. However, it requires specialized equipment and may involve a steeper learning curve.

5. Axial Spray Transfer Mode

Characteristics: Axial spray transfer is a variation of the spray transfer mode where the electrode wire is positioned axially within the gas shield, promoting a straight and focused arc.

Applications: This mode is used in critical welding applications, where precision and control are essential.

Advantages and Disadvantages: Axial spray transfer offers exceptional control and minimal distortion but requires careful torch angle and travel speed management.

Quality and Safety Considerations

Ensuring quality in GMAW welding involves addressing common issues such as dross and porosity. A common problem in aluminum GMAW, can be caused by oxides on the electrode, base materials, or insufficient shielding gas. Proper cleaning and shielding gas flow are essential to minimize dross formation.

Porosity occurs when gas becomes trapped in the weld pool and solidifies before it can escape. To reduce porosity, the workpiece and electrode must be clean, welding speed controlled, and heat input balanced. Preheating can also help in some cases.

Safety is paramount in GMAW. Welders must wear appropriate protective clothing to shield against intense heat, sparks, and UV radiation. Proper ventilation is necessary to prevent exposure to hazardous gases and fumes. Flammable materials should be kept away from the work area, and a fire extinguisher should be readily available.

In summary, Gas Metal Arc Welding (GMAW) is a widely used welding process that offers versatility and ease of operation. It has various applications, depending on the materials and process variations used. To ensure high-quality welds and safety, proper equipment, operator training, and control of welding parameters are essential. Understanding the metal transfer modes in GMAW is crucial for selecting the appropriate mode for a given welding task.

GMAW Welding FAQs

What is GMAW welding?

GMAW welding is a welding process that uses a consumable electrode wire, an electric arc, and a shielding gas to join metals. It’s widely used for welding steel, aluminum, and other metals.

What are the main components of a GMAW welding setup?

A typical GMAW welding setup includes a power source, a wire feeder, a welding gun or torch, a spool of welding wire, and a gas cylinder with a regulator for shielding gas.

What is the role of the shielding gas in GMAW welding?

The shielding gas (typically argon, carbon dioxide, or a mixture of gases) is used to protect the molten weld pool from atmospheric contamination. It prevents oxidation and ensures a clean and strong weld.

What materials can be welded using GMAW?

GMAW can be used to weld a wide range of materials, including carbon steel, stainless steel, aluminum, and various alloys. The choice of welding wire and shielding gas depends on the material being welded.

What are the advantages of GMAW welding?

Some advantages of GMAW welding include high welding speed, versatility in welding various materials, good control over the welding process, and minimal spatter when set up correctly.

How does GMAW differ from GTAW (Gas Tungsten Arc Welding)?

GMAW uses a consumable wire electrode and is generally faster than GTAW, which uses a non-consumable tungsten electrode. GTAW is often used for precision welding on thinner materials and non-ferrous metals.

What are some common applications for GMAW welding?

GMAW is used in various applications, including automotive manufacturing, construction, shipbuilding, and general fabrication. It’s also commonly used for repairing and maintaining metal structures.

What safety precautions should be taken when GMAW welding?

Safety is crucial when GMAW welding. Operators should wear appropriate personal protective equipment (PPE), work in a well-ventilated area, and be aware of electrical hazards and potential fire risks. Proper training is essential.

How do I choose the right welding wire and shielding gas?

The choice of welding wire and shielding gas depends on the material you’re welding and the specific requirements of your project. Consult your welding equipment manufacturer’s recommendations and consider factors such as base metal type, thickness, and welding position.

What are some common troubleshooting issues in GMAW welding?

Common issues include poor penetration, excessive spatter, porosity, and incomplete fusion. These problems can be caused by incorrect settings, contaminated materials, or improper welding technique. Understanding and addressing these issues is essential for producing high-quality welds.