Hot cracking is a metallurgical phenomenon that often occurs during welding and casting processes, leading to structural defects and compromised material integrity. Understanding hot cracking and its causes is crucial for engineers, welders, and anyone involved in the fabrication of metal components. In this blog, we will delve into the world of hot cracking weld defect, exploring what it is, how it occurs, and strategies to prevent it.

What is Hot Cracking?

Hot cracking, also known as solidification cracking or liquation cracking, is a type of weld defect that manifests as cracks in the welded or cast metal, particularly in the heat-affected zone. These cracks can severely compromise the structural integrity of the material. Hot cracking is a common issue in various industries, including construction, automotive, aerospace, and manufacturing.

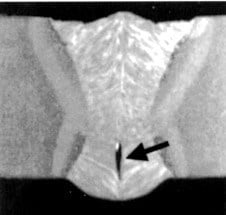

These fissures are referred to as ‘hot cracks’ due to their occurrence right after or even during the welding process, typically when the weld metal begins to solidify from the edges of the base metal it is joining. As the solidification process advances, the low-melting-point eutectics become concentrated at the center and stay in a liquid state. This liquid phase is subsequently subjected to the stresses inherent in welding, leading to the formation of a crack along the central line. Hot cracking is the formation of shrinkage cracks during the solidification of weld metal. This phenomenon occurs in almost all metals.

Hot cracking usually occurs longitudinally along the weld axis, occurring at the middle of the weld, however it can also take place across the weld axis affected by the direction of tensile stress.

Causes of Hot Cracking

The main causes/factors of solidification cracking can be categorized as: high strain on the weld pool, insufficient quantity of liquid weld metal, and impurities. Thus, hot cracking occurs when:

- Presence of impurities such as sulfur (S) or phosphorus (P) are present which have lower melting point

- A blockage or insufficient supply of weld liquid (filler metals/material) prevents areas being reached

- Strain on the weld pool is too high, Low ductile material more likely to have hot cracking due to less plastic deformation

Prevention of Hot Cracking

Hot cracking can be prevented by employing adequate precautions as discussed below, except for some alloys that are inherently very susceptible to hot cracking in arc welding.

- Reducing heat input: The use of lower heat input increases the cooling speed of the weld metal, which minimizes the time spent in the brittle temperature range. It also increases the width-to-depth ratio of weld metal, thereby decreasing the susceptibility to hot cracking.

- Weld metal composition : The composition of weld metal affects hot cracking in welding by influencing the material’s solidification range, promoting the formation of low-melting eutectic phases, introducing impurities that can serve as crack initiation sites, and affecting hydrogen content. Proper alloy selection, minimizing impurities, and controlling hydrogen levels are crucial to prevent hot cracking and ensure a strong, crack-free weld.

- Strain on the solidifying weld metal : Strain on solidifying weld metal is a key contributor to hot cracking in welding. Rapid cooling and solidification generate residual stresses within the material, increasing the likelihood of cracking. The reduced ductility caused by strain and stress can make the material more brittle, facilitating crack formation and propagation. To prevent hot cracking, proper techniques like preheating and controlling the cooling rate are essential for managing strain-induced stress and preserving the weld’s integrity.