In various industries, from construction to manufacturing, understanding the weight of pipes is crucial for planning, safety, and cost estimation. A pipe weight calculator is an essential tool that simplifies this process, allowing engineers, architects, and contractors to quickly determine the weight of a pipe based on its material, dimensions, and length. This article explores how pipe weight calculators work and why they are important.

A pipe weight calculator uses a simple formula to calculate the weight of a pipe: Weight=Volume×Density\text{Weight} = \text{Volume} \times \text{Density}Weight=Volume×Density

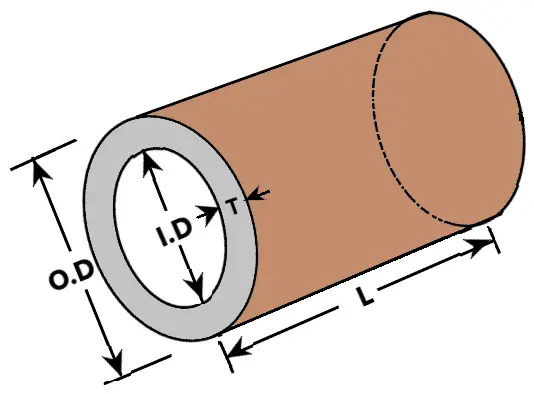

For cylindrical pipes, the formula considers the pipe’s dimensions:

Weight = Volume x Material Density

OD = Outside Diameter of Pipe

ID = Inside Diameter of Pipe

ID = OD – 2T

T = Thickness of Pipe L=Length of Pipe

Volume of Pipe = π⁄4 (OD²-ID²) x L

Weight of Pipe = π⁄4 (OD²-ID² ) x L x Material Density

Different materials have different densities, which significantly affect the pipe’s weight. Here are some common materials used in pipes and their typical densities:

- Steel: 7850 kg/m³

- Aluminum: 2700 kg/m³

- Copper: 8960 kg/m³

- PVC: 1380 kg/m³

Other Weight calculators