Welding plays a critical role in the fabrication and assembly of metal structures, and one of the most commonly used types of welds in engineering and construction is the fillet weld. Whether used in T-joints, lap joints, or corner joints, fillet welds are known for their ease of application and strength. However, to ensure the integrity and reliability of these joints, it’s important to understand what determines the strength of a single fillet weld joint.

What is a Fillet Weld?

A fillet weld is a type of weld that joins two pieces of metal at approximately right angles to each other. It typically forms a triangular cross-section and is commonly used in T-joints, lap joints, and corner joints. The fillet weld can be applied on one side (single fillet) or both sides (double fillet), depending on the design and loading conditions.

Factors Affecting the Strength of a Fillet Weld Joint

The strength of a fillet weld joint is influenced by several factors:

- Size of the Weld (Leg Size): The leg size is the length of the two sides of the weld triangle. A larger leg size generally increases the weld strength, but only up to an optimal point.

- Shape and Quality of the Weld: A properly shaped and defect-free weld ensures good load transfer and prevents stress concentrations.

- Type of Base Metal: The strength of the metals being joined impacts the overall joint performance.

- Welding Process Used: Different welding processes (e.g., GMAW, SMAW, TIG) offer different penetration, heat input, and control.

- Cleanliness and Preparation: Dirty, rusty, or poorly fitted materials can weaken the weld and reduce strength.

- Weld Length: The total length of the weld contributes linearly to the total joint strength.

Calculating the Strength of a Single Fillet Weld Joint

Let’s walk through an example of calculating the strength of a single fillet weld joint using the Gas Metal Arc Welding (GMAW) process.

Assumptions:

- Welding Process: GMAW (Gas Metal Arc Welding)

- Leg Size of Fillet Weld: 12 mm

- Material: Mild Steel

- Ultimate Tensile Strength (UTS): 450 MPa (approximate value for mild steel)

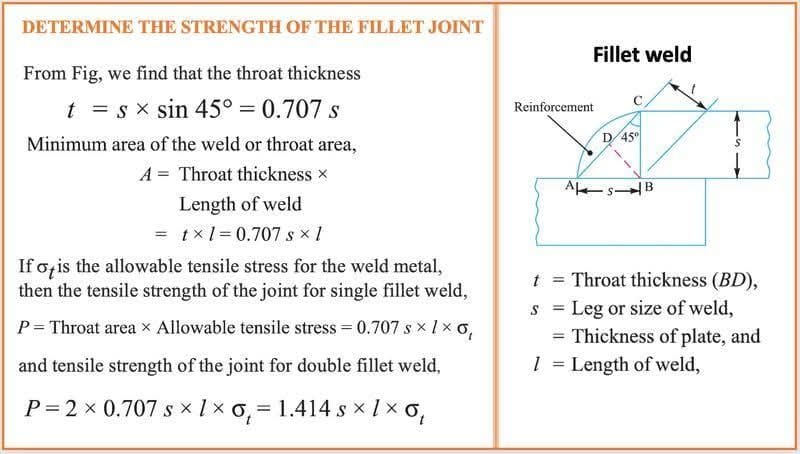

Step 1: Determine the Throat Thickness

The effective throat thickness is the shortest distance from the root of the weld to the face of the weld. For a fillet weld, it is calculated as:

Throat thickness (t)=Leg size×0.707

t=12mm×0.707=8.48mm

Step 2: Determine the Allowable Shear Stress

The strength of the weld is limited by the shear strength of the metal at the weld throat. For fillet welds, a typical assumption is:

Allowable shear stress=0.3×Ultimate Tensile Strength (UTS)

=0.3×450MPa=135MPa

Step 3: Calculate Strength per Unit Length

Now, we calculate the strength of the weld per millimeter of length:

Strength per unit length=Throat thickness×Allowable stress

=8.48mm×135MPa=1144.8N/mm

This means that each millimeter of the weld length can carry approximately 1145 newtons of load.

Important Considerations

Over-Sizing Welds: While increasing weld size can increase strength, excessive weld size may cause stress concentrations, distortion, or unnecessary heat input, potentially weakening the joint.

Double Fillet Welds: Using welds on both sides of the joint can effectively double the load-carrying capacity.

Joint Design: Always consider joint geometry and the type of load (tensile, shear, bending) when designing welds.

Quality Control: Non-destructive testing (NDT), such as ultrasonic or radiographic inspection, helps verify weld quality in critical applications.

Conclusion

A single fillet weld joint, when properly designed and executed, provides robust and reliable strength in a variety of structural applications. In our example using a 12 mm leg size fillet weld on mild steel with GMAW, we calculated a strength of approximately 1145 N/mm of weld length. Understanding the influence of weld size, metal type, welding method, and proper calculation helps engineers and fabricators create safer and more efficient welded structures.

By ensuring the correct weld dimensions and following industry best practices, the performance of a fillet weld joint can be optimized to meet the demands of modern engineering applications.

Join us on other platforms

Instagram : https://www.instagram.com/weldfabworld

YouTube : https://www.youtube.com/@weldfabworld

X Account : https://x.com/Weldfabworld

Telegram : https://t.me/weldfabworld

WhatsApp Channel : https://whatsapp.com/channel/0029Va5YviXCcW4ksGsjNz1G