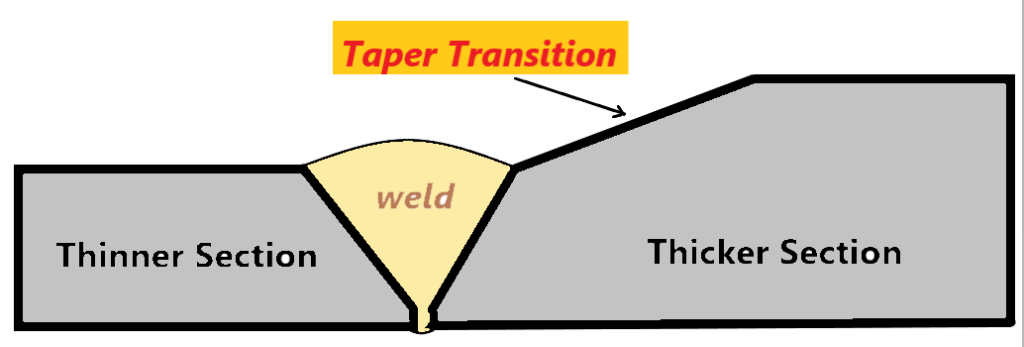

In this article we will discuss about the taper transition requirement for dissimilar thickness as per ASME Section VIII Division 1:

What is Taper Transition?

Transition is formed by removing the material by grinding or machining from the thicker material section to match it with the thinner section’s thickness.

When Taper Transition required?

Taper transition is required when the thickness of thicker member differs by more than ¼ of the thickness of the thinner member or by more than 3 mm whichever is less.

Why is Taper Transition required?

At the juncture of two dissimilar thickness shells, shear and bending moments arise which raise the stress level above the desired membrane stress. So, taper transition is necessary to minimize the effects of these discontinuity forces and moments, and a shell structure will result in that has nearly constant strength.

How much Taper Transition is required?

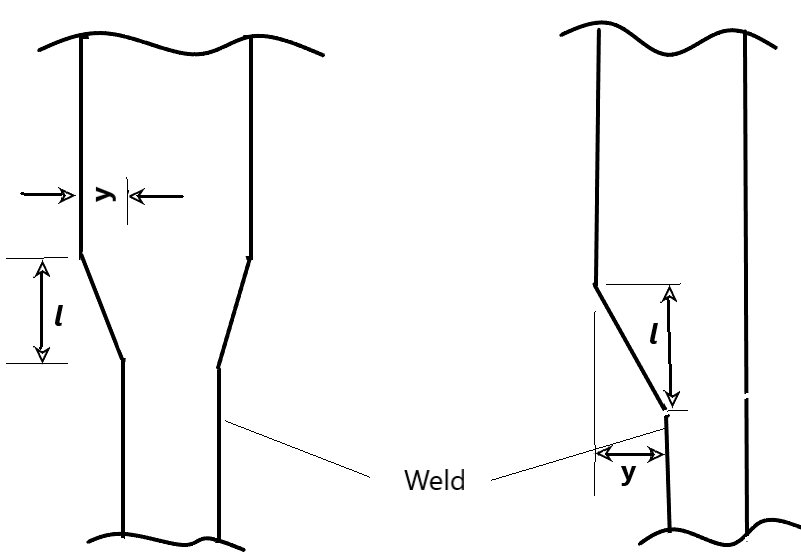

Minimum 1:3 taper transition required as per ASME Section VIII Div. 1, UW-9.c

l= Required length of taper

y= offset distance between adjacent surfaces of abutting sections

l ≥ 3y (in all cases, l shall not be less than 3y).

Exercise Question: If there are two plates with different thicknesses of 20 mm and 14 mm. To connect the shell, both will be welded, then how much taper transition is needed?

y = offset distance between adjacent surfaces of abutting sections

= 20-14 mm = 6 mm

l =3y minimum = 3 x 6 =18 mm minimum

Procedure qualification requirement of unequal thickness joint with taper transition:

When the thicker test coupon is tapered to provide a transition at the Weld, the qualified range shall be based on the base metal thickness adjacent to the toe of the Weld at the thinnest end of the transition. The test specimen for the tensile and bent test may be machined to the thickness required for the thinner base metal prior to testing.