The ASME #B31.1 – 2022 Power Piping Code plays a pivotal role in ensuring the integrity and safety of power piping systems. One crucial aspect of this code is the meticulous examination and testing of welds to ascertain their quality and structural soundness.

In this article we will discuss visual examination as per Chapter VI of the ASME B31.1 code, titled “Inspection, Examination, and Testing,” is dedicated to this critical aspect of power piping, offering detailed guidelines and criteria for evaluating weld defects. These criteria are essential to maintain the reliability of piping systems, especially in high-pressure and high-temperature applications.

Visual Examination as per B31.1(Paragraph 136.4.2): Visual inspection is the most fundamental method, involving a thorough visual examination of welds. The code provides clear criteria for rejecting welds with visible defects, such as cracks on the external surface, lack of fusion, incomplete penetration, and excessive weld reinforcement.

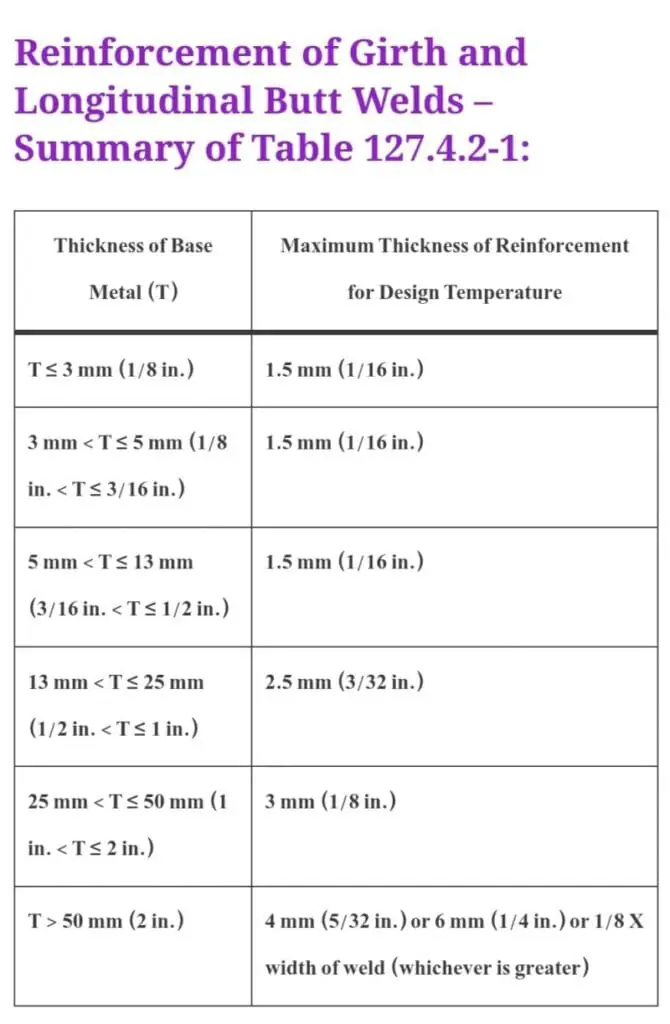

#Weld #defect acceptance/rejection criteria for visual Inspection: Cracks on the external surface are unacceptable. Lack of fusion on the surface is unacceptable. Incomplete penetration is considered unacceptable if the inside surface is accessible. Weld reinforcement exceeding specified limits, as detailed in the table below, is unacceptable.

Undercut greater than 0.8 mm (1/32 in.) deep or exceeding the minimum required section thickness is unacceptable. Surface undercut on longitudinal butt welds is unacceptable. Any linear indications greater than 5 mm (3/16 in.) in length are considered unacceptable. Surface porosity with rounded indications having dimensions greater than 5 mm (3/16 in.) or with four or more rounded indications separated by 1.5 mm (1/16 in.) or less edge to edge in any direction is unacceptable. Arc strikes outside of the weld joint are unacceptable.