Welding symbols are graphical representations used in engineering and manufacturing to communicate important information about welds in a standardized and easily understandable manner. These symbols are crucial for ensuring accurate and consistent communication between designers, engineers, fabricators, and inspectors involved in the welding process.

Here are some reasons highlighting the importance of welding symbols:

- Clarity and Consistency:

- Precise Communication:

- Less Rework/Efficient Production means cost saving

- Easy Documents and record keeping for future

A distinction is made between the terms “weld symbol” and “welding symbol.”

- The weld symbol indicates the desired type of weld.

- The welding symbol represents the weld symbol on drawings.

1. Components of AWS Welding Symbols

Understanding the components of AWS welding symbols is essential for effective interpretation:

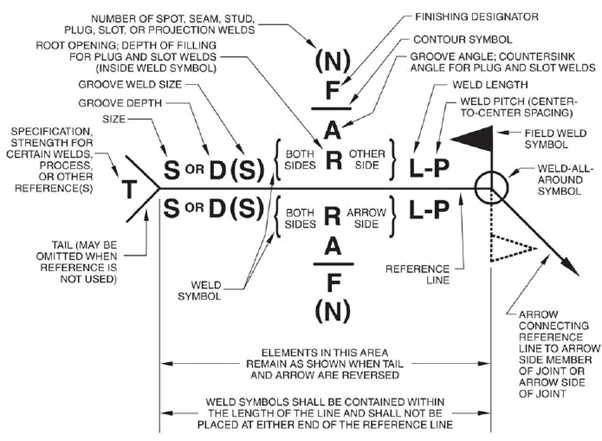

Fig 1.1

1.1 Reference Line

The horizontal line — called the reference line — is the anchor for all welding symbols. You’ll find instructions for making the weld strung along the reference line. An arrow connects the reference line to the joints that to be welded. In the example above, you’ll see the arrow growing out of the right end of the reference line and heading down(See fig 1.1) and to the right, but standards allow many other combinations.

1.2 Arrow

The arrow points to the area where the weld is to be applied. The tail of the arrow connects to the reference line, and the head points to the joint’s location. See arrow in fig 1.1

Any welded joint indicated by a symbol will always have an arrow side and an other side. Accordingly, the terms arrow side, other side, and both sides are used herein to locate the weld with respect to the joint.

1.3 Basic Weld Symbols

Basic symbols, such as fillet, groove, plug, and spot weld symbols, represent the type of weld required. These symbols are often accompanied by supplementary symbols that provide additional information.

The weld symbols represents a type of weld and, when used, is a part of welding symbol.

Weld symbols are used to indicate the welding processes used in metal joining operations, whether the weld is localized or “all around”, whether it is a shop or field weld, and the contour of welds.

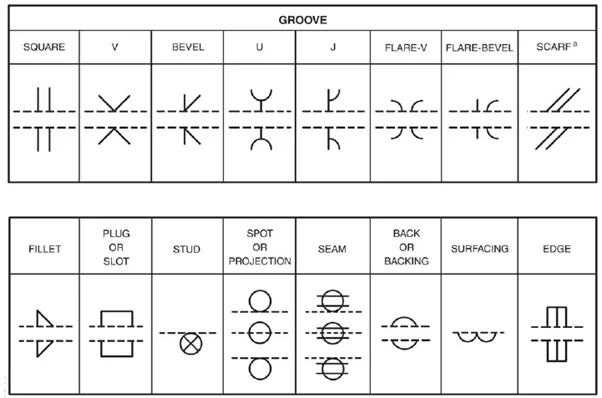

Weld Symbol shall be shown as below in fig. 1.2. The symbol shall be drawn in contact with the reference line.

Fig 1.2

These basic weld symbols (arc and gas weld symbols, resistance weld symbols, brazing, forge thermit, induction, and Flow Weld Symbols) are summarized below

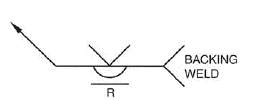

1.4 Supplementary Welding Symbols

These symbols are used in many welding processes in congestion with welding symbols and are used as shown below in fig 1.3

Fig 1.3

1.5 Tail in Welding Symbols

The tail of the symbol is used to designating additional information such as specification, process, strength for certain welds, identification of the filler metal or electrode, peening, backgouging, or other operations or references necessary for making the weld as shown some examples below in fig 1.4

Fig 1.4 (Tail Showing information)

1.6 Placement of Welding Symbols

The arrow of the welding symbol shall point to a line, location, or area that conclusively identifies the joint, location, or area to be welded.